grinding mill maintenance

مجال التطبيق

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

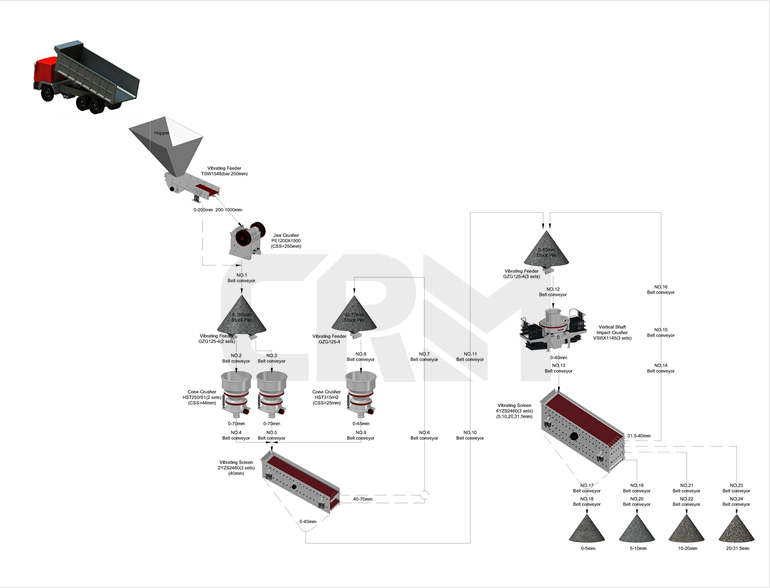

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

What Preventative Maintenance of Grinding Machines Can

2020年11月3日 UNITED GRINDING recommends preventive maintenance of the machines every 2,080 operating hours; this corresponds to one 8-hour shift per day, 5 days a week over a year. If the grinding machine is used in two shifts per day, the

ABB Ability™ Predictive Maintenance for grinding

ABB Ability™ Predictive Maintenance for grinding based on the condition monitoring solution provides an easy access to GMD system parameters and visualization, taking a

Predictive maintenance in mining industry: grinding mill case study ...

2022年1月1日 The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the

Mill Maintenance Plan: 3 Steps That Maximize Mill

2014年7月15日 Velocity Chemicals Mill Maintenance Plan: 3 Steps That Maximize Mill Productivity and Lower Costs It is a sad fact that in many processing operations across

Minding the Grind: Maintenance Options to Keep SAG

“In wet grinding mill applications, slurry can seep underneath trunnion or shell liners and start washing the mill components, particularly when the liner rubber backing is missing or damaged. Often, this goes

Predictive maintenance in mining industry: grinding mill case study

2022年10月19日 This work aims to present a state of the art of recent works in predictive maintenance using machine learning algorithms including deep learning algorithms to

Full asset availability with Predictive Maintenance for

ABB Ability™ Predictive Maintenance for grinding is a unique digital solution to maintain, assess and analyze your GMD system.The solution, based on condition monitoring, provides easy access to GMD system

Ball Mill Cleaning Maintenance Guide: Extending

2023年12月6日 To further enhance your ball mill’s performance and extend its operational life, consider implementing these best practices: Optimize the Grinding Process: Adjust the ball size, distribution, and fill

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت